ARBOCEL® – Functional Additives for Saving Energy and Costs

The Right Solution for Saving Energy and Costs

In times of exploding energy prices and climate change, the call to save energy, thereby helping the environment and staying competitive is greater than ever before. While the currently established plants to produce pulp materials have little room to adjust the process and forward the increasing costs further down to the paper mills, water the other crucial resource for the paper industry is also getting more and more valuable. Meanwhile, new pulp plants like steam explosion ones are not on a competitive large scale available, yet. Therefore, a convenient step would be to reduce energy consumption. One way to achieve this goal is to adjust paper formulation.

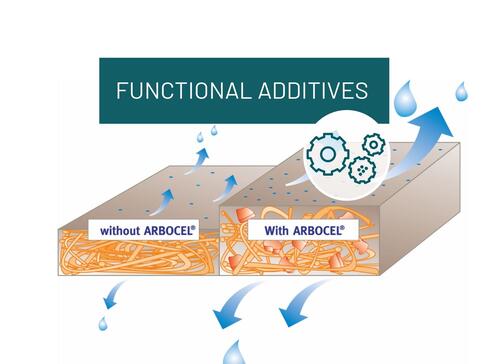

An ideal solution to this problem does minimize the impact on mechanical parameters and is itself renewable like the pulp. The largest lever to reduce the energy consumption of the plant is certainly the drying section. Precisely milled ARBOCEL® wood particles hold canals in the paper open and thereby increase the drainage. This small adjustment in the formulation can therefore decrease the energy to dry the paper and increase machine speed. In addition, as few as 3% of ARBOCEL® particles improve the bulk of the paper, can reduce the cost and replace chemical bulk additives.

Mobile support: At JRS we do not settle with simply supplying the raw materials, but support our customers with all trials and tests. A purpose for which we constructed our mobile dosing unit for big bags. The unit can transport the ARBOCEL® via hoses to a defined segment in the paper machine and be a bridging solution to introduce ARBOCEL®.

Quick hint: Check out our previous blog entries to learn more about alginate coatings as a renewable solution to oxygen and grease barriers for paper & packaging.

Level Up Your Paper & Packaging with Every Fiber.

Plant-based solutions for application in the paper & packaging industry.