Our Best-Performing Hydrocolloids, Unmatched Potential

Rethinking Formulations

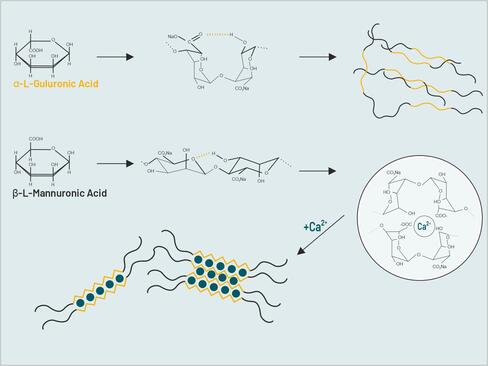

A main function of every rheology additive is to thicken the solution to the desired viscosity. Of the two products we are looking at, alginates and Microcrystalline Cellulose Gels (MCG), both do this well over a wide pH range. Furthermore, MCGs show excellent stabilizing properties even at low viscosity and quantity. Alginate on the other hand do only stabilize dispersions after their gelling reaction with multivalent cations such as calcium cations. The reaction of calcium with alginate is shown in figure 1.

This gelling reaction with calcium happens exponentially. This means low concentrations of Calcium cations below 0.033% do normally not induce gelation. Therefore, average quantities and fluctuations of calcium in tapwater do not hinder the production process and various pre-gels can be formed.

The Bio-Based Performers

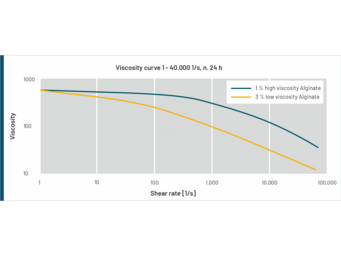

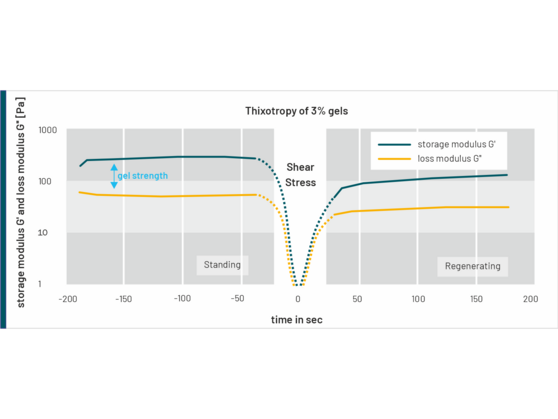

While alginate gel-networks are irreversibly destroyed by high shear energy and then form lumps, un-gelated alginates are shear thinning. Here, higher viscosity ones show a more intensive behavior than low viscosity alginates at the same viscosity (figure 2). Regarding the impact of shear stress, MCGs show intriguing properties. Due to a thixotropic character of MCG containing solutions (as seen in figure 3), they are ideal candidates for e.g. spraying applications and defined destabilization of static dispersions during application.

But how resilient are these networks? In fact, microcrystalline cellulose gels and alginates have a broad tolerance to pH values and in case of MCGs even to temperature. MCGs show a pH stability between 4 and 10, while alginates on their own are stable between 4 to 8.

Regarding temperature stability, MCG gels and alginate, which was gelled with calcium, maintain the gel character even at higher temperatures. However, in contrast to MCGs, alginates will undergo a degradation process at elevated temperatures. This has to be considered during formulation design. Nonetheless, the chemically unmodified nature of alginates and their tunability through the ion content make them excellent components of bio-based and renewable adhesive and coating systems. Furthermore, the unique synergies with other hydrocolloids such as pectins offers countless opportunities for tailoring your unique formulation.

Contact us to Speak about your Specific Application and Needs!

Level Up Your Glues & Adhesives with Every Fiber.

We supply bio-based rheology additives and fillers for adhesives in home and industrial applications.