Developing Formulations – Ultra-Fine and Pure Cellulose

How Small can you get Before it gets “Nano”?

First of all, we hope you had a pleasant New Year’s Eve and enjoy our first blog entry in 2022.

For many this question is easily answered, we have a defined scale and below a certain average length and thickness, we have a nano-fiber. However, for us it can also mean something else. With most nano-cellulose-fibers widely discussed in the academic research, severe economic hindrances occur, unfortunately in addition to the well-described benefits. The need to have low solid solutions or gels ultimately complicates handling, increases shipping cost and therefore prevents a large-scale usage and production of nano-fibers. In the meantime, until these challenges are solved satisfactorily (which I think they will), JRS developed other ultra-fine and pure cellulose fibers for specific customer needs.

This development resulted in two interesting and commercially available products:

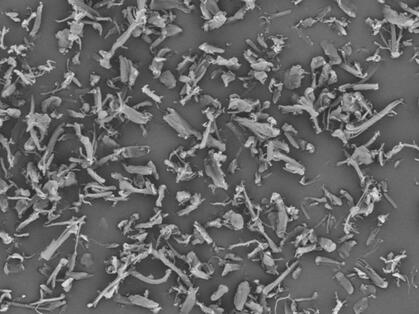

- The ultrafine cellulose: UFC-100 microcrystalline particles

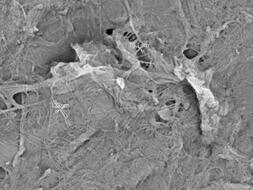

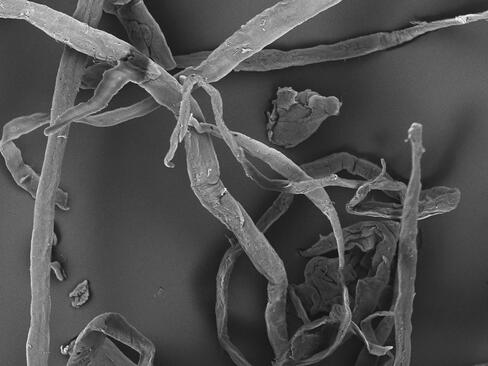

- The wheat fiber gel: WFG-HS 73 microfibrillated fibers

Both products are delivered as solid powders and can be dispersed in the customer system. To prevent agglomeration during storage, the WFG contains a spacer, which is introduced in a unique process.

Going up the Size

Beside the good properties perfect suitability as rheology agent and sheer thinning additive, an alginate film or coating has outstanding properties regarding oil and ox-ygen barrier.

With the right plasticizer and alginate grade, our R&D was able to generate a ~50 µm free alginate films with oxygen transmission rates (OTR) below 1.0 cm³ / (m² * d * 1.0 bar) @ 25°C and 50% relative humidity. Since this was possible in simple formula-tions without fine-tuning and basic equipment, a huge potential is expected in this field. Alginate containing films or coatings could therefore replace e.g. EVOH in packaging applications. In addition, these films are perfect oil barriers, passing the KIT 12 test easily.

While the films are hydrophilic by nature, they can be water insoluble or soluble de-pending on the content of Calcium. And best of all, they are completely bio-degradable! Nonetheless, we have to admit that some challenges remain, such as seal-ability of the films and the integration into water-proof multilayer systems. How-ever, we are convinced that these challenges will be solved by the industry.

Due to its small size, UFC-100 is used in various established applications, for example as pore creator in ceramics for catalysts or as additive for artificial leather to increase foam volume. While the UFC-100 lacks the material reinforcement properties, which are often described for nanofibers in the literature, larger cellulose fibers in the JRS portfolio have a higher L/D ratio and offer reinforcing properties.

What is Next?

We believe nanofibers are not around the next corner and in the meantime we work on strengthen microfibers and further extend the applications of high L/D ratio cellulose. For example to improve the workability with polymer matrices and extend the knowledge of effects from cellulose fibers in biopolymer-composites. So stay tuned for another year with our blog articles, we have some interesting topics coming up!