Agents for Roller Press Compaction, Build-up Agglomeration and Anti-caking

Natural and Intelligent Fiber Agents for the Production of Broken Fertilizer Granules and Prills

Choose the most modern and sustainable way to optimize your production of fertilizer granules, prills and mini prills:

Building on experience in virtually every industry sector, JRS Plant Fiber Agents have proven to be true solution providers in roller compaction, build-up agglomeration and problem solving for anti-caking or dust reduction!

Perfect Fusion! Our Technology, Your Experience.

We utilize all the possibilities of JRS Plant Fiber Technology to work together and create the optimal solutions for your needs. Your challenges are our passion!

What does value-added cooperation with JRS look like?

YOUR CHALLENGE:

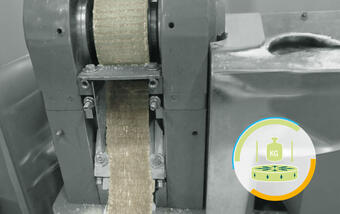

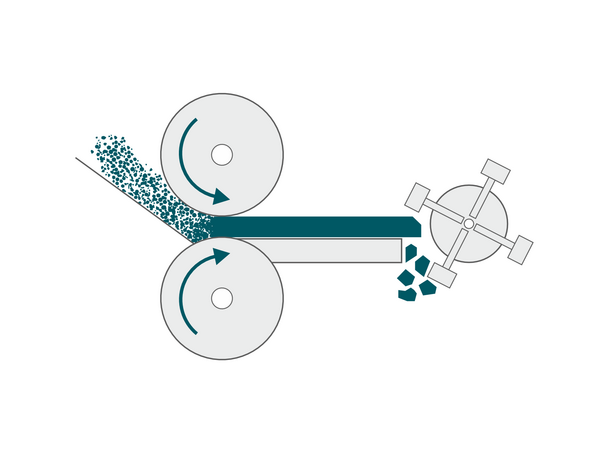

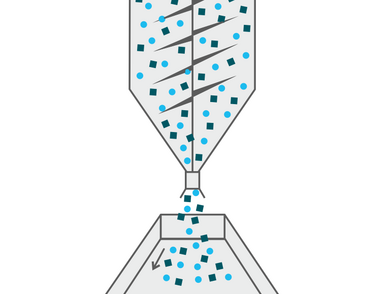

How to Improve Roller Compaction?

Problem description:

Material mix is often difficult to process. Too much scrap material is produced in the compression process. End products become inhomogeneous, too brittle or have low abrasion resistance.

How to Solve It

By improving the compressibility of the material during roller compaction, the compressing process runs more smoothly and the product properties of broken granules, prills and mini prills can be optimized.

Which Fiber Works

Compression agents of the ARBOCEL® Fiber Group

Contact us for the identification of the right compression agent which strongly depends on the physical conditions of your fertilizer.

How It Works

ARBOCEL® Fibers in the dry premix ease the compression with simultaneous control of elasticity and density. The fibers create a stable microstructure under rolling pressure.

How to Use It

Required quantity in dry premixes depends on specific fomulation of the fertilizer. Individual consulting is offered by the JRS Technical Application Center.

Improve Your Compaction Process

- More homogeneous premixes: no material clumping

- More stable granules with uniform and lower roll pressure with less energy consumption, less machine wear, with less heat development

- Consistent, uniform compaction, despite high material thickness

- Thicker compressed layer possible

- Less fines during final breaking step into granules

- High throughput, increased efficiency

… and Granule Properties!

- Granulate particles become more abrasion resistant

- Particle shape, structure and size can be adjusted to all common application techniques for granuled fertilizer

- Anti-caking: no clumping of the finished granules

YOUR CHALLENGE:

How to Improve Classical Build-up Agglomeration?

Problem description:

Many components of formulations make it hard to achieve a smooth and fast granulation. Granules become irregular in shape, size and their composition gets inhomogeneous. The manufacturing process takes longer than necessary.

How to Solve It

By optimizing the adhesion between the particles, granulation in build-up agglomeration will be more consistent and smooth. As a result, the product properties of the granules can be optimized.

Which Fiber Works

HPMC binders* of the ARBOCEL® Fiber Group.

How It Works

Formation of a bonding bridge by means of a thin elastic film, which is created using HPMC binders. This results in a strong, elastic cross-linking of all particles.

How to Use It

Addition of 2-6% HPMC solution depending on required viscosity.

* 100% plant fiber, non ionic, non toxic, soluble in cold water, enzyme resistant ph stable (ph 3-11), big range of viscosities (3-40000 mPas)

Improve Build-up Agglomeration

- Fast, consistent agglomeration

- Suppression of dust formation

… and Optimize Your Granule Structure!

- Uniform size

- Consistent weight

- Free-flowing

- Break resistant, low abrasion due to closed surface ideal for all common dosing techniques like scatter dosing and point dosing.

YOUR CHALLENGE:

How to Avoid Clumping, Incrustation or Lump Formation?

Problem description:

Individual components in fertilizer powders and granules react differently to humidity or temperature fluctuations. Surfaces cake and stick together during or after the production process. The application of the final product is disrupted and shelf life is reduced.

How to Solve It

Prevent clumping and incrustation of granules, prills or mini prills by adding an effective anti-caking agent. Their flowability is thus permanently maintained, from the production process to the application by the end user.

Which Fiber Works

Anti-caking agents of the product group ARBOCEL®. Contact us for the identification of the right anti-caking agent which strongly depends on the physical conditions of your fertilizer.

How It Works

ARBOCEL® acts as a spacer between the clumping particles and also absorbs excess moisture not being available anymore for the particles to adhere to each other.

How to Use It

Addition of ARBOCEL® anti-caking agent in the powder mix or final granulated product. Required quantity depends on the fertilizer properties.

Profit from Anti-Caking Effects in Your Production Process

- Improved flowability in production and filling process

- Reduce production scrap

… in Storing and Application of Fertilizer Granules!

- Avoids clumping, incrustation and lump formation during storage and transportation

- Physical properties and quality of the fertilizer product are maintained until application by the end user

Liquid to Solid Carrier

Conversion of various liquids (e.g. oils) into processable powders and granules: The application of liquids on inert JRS Fiber Carriers offers a smart way of integration in dry formulations. This opens up new possibilities in your recipes, even in very low concentrations.

Further Challenges and Solutions in Fertilizer

JRS Plant Fiber Technology has built a total-care system that focuses on all kinds of fertilizers. Using our functional plant fibers you can improve your production processes and optimize fertilizer properties in many ways.

Liquid Fertilizers

Our Team is Happy to Support You

with any requests you have.

Please use the contact form below.

Phone consultation: +49 7967 152-424