Rheology Agents: Anti-settling, Sprayability,

Anti-run-off

Intelligent and Natural Fiber Agents for the Production of Liquid Fertilizers

Choose the most modern and sustainable way to optimize your production of liquid fertilizers:

Building on experience in virtually every industry sector, JRS Plant Fiber Agents have proven to be true solution providers in managing properties of all liquid substances. In fluid fertilizers and gels any kind of requirements in anti-settling, sprayability, anti-rinse-off, thixotrophy and thickening can be managed by our organic agents.

FiBL listed: All of our agents can be FiBL listed and thus are suitable for the organic farming and horticulture as well.

Your Challenges Are Our Passion!

Perfect Fusion! Our Technology, Your Experience.

We utilize all the possibilities of JRS Plant Fiber Technology to work together and create the optimal solutions for your needs. Your challenges are our passion!

What does value-added cooperation with JRS look like?

YOUR CHALLENGE:

How to Avoid Settling, Flocculation, Floating and Sedimentation?

Problem description:

In liquid formulations, the different physical characteristics of its components make it difficult to reach a long-term homogeneous and stable composition. Segregation processes limit the shelf-life and applicability of the liquid product. The use of common stabilizers, such as Xanthan Gum, is limited by the tolerance against ph values or by fast microbiological spoilage.

How to Solve It

Replace conventional stabilizers, such as Xanthan Gum, and stabilize the dispersion in a permanent and reliable manner.

Which Fiber Works

Microcrystalline Cellulose Gels (MCG) from the VIVAPUR® and ARBOCEL® Fiber Group

How It Works

MCG products build up a stable fiber network in fertilizer dispersions, which keeps unsoluble components in suspension. The broad range of MCGs resists the impact of low and high ph values. They provide a full microbiological stability.

How to Use It

0.5- 2.5% addition in water and activation by shear forces before adding fertilizer components. Direct activation in the fertilizer solution is also possible but requires higher shear forces.

Simplify Your Mixing Process

- Easy and fast preparation of a MCG solution

- Easier processing in comparison to Xanthan Gum, due to better gel consistency

- Advantages in formulation due to pH value tolerant stabilization

… and Create Stable Dispersions!

- Longer shelf life due to longer system stability of the dispersion and due to microbial stability of MCG compared to Xanthan Gum

- No subsequent stirring necessary before application

- Stable, homogeneous active ingredient composition during application, especially with regard to trace nutrients

- Can be stored at temperatures below 0° Celsius: MCG prevents crystalisation

YOUR CHALLENGE:

How to Improve Sprayability?

Problem description:

Rheology control by synthetic polymers and silicones sometimes impair sprayability. This is why fine spray patterns cannot be produced with simple spray lances. Spray angles are difficult to adjust, break out and an uneven drip pattern causes the fertilizer to be distributed unevenly on the leaf. Therefore precise dosing becomes impossible.

How to Solve It

Influence the spray parameters by controlling viscosity to improve the sprayability of your fertilizer dispersion, i.e. separation into fine droplets, with narrower spray angle and consistent spray pattern.

Which Fiber Works

Microcrystalline Cellulose Gels (MCG) from the VIVAPUR® and ARBOCEL® Fiber Group for use in sprayable foliar fertilizers, as a plant-based alternative to synthetic polymers and silicones

How It Works

JRS colloids increase the molar mass in the dispersion and enable higher viscosity and thus smaller, more consistent droplets.

How to Use It

0.5- 2.5% addition in water and activation by shear forces before adding fertilizer components. Direct activation in the fertilizer solution is also possible but requires higher shear forces.

Formulate Without Silicon!

- Formulation benefit: suitable for silicon-free products

- Simplified equipment cleaning compared to the use of polymers and silicones

Create Products That Are Better and Easier to Spray!

- More targeted and thus more efficient application enables lower consumption quantities

- Product application requirements are simpler, as product can be applied with simple spray technology, e.g. flat-fan nozzles instead of more expensive spray technologies like low-drift nozzles

YOUR CHALLENGE:

How to Avoid Draining, Dripping and Run Off Problems?

Problem description:

When sprayed in foliar application the liquid fertilizer forms larger droplets and drips or runs off the plant. The fertilizing effect is minimized or wasted. Leaching by rain also results in a fertilizer loss and causes e.g. unwanted nitrogen inputs to soil and surface waters.

How to Solve It

Control viscoelasticity to prevent liquid fertilizer from running off and dripping.

Which Fiber Works

Microcrystalline Cellulose Gels (MCG) from the VIVAPUR® and ARBOCEL® Fiber Group for use in sprayable foliar fertilizers

How It Works

Due to their special structure JRS colloids form a strong fiber network. This provides high gel strength even at lower viscosity levels. This is how a stable film on the plant surfaces can be created. The nutritional effect to the plant is prolonged and used to full capacity.

How to Use It

0.5- 2.5% addition in water and activation by shear forces before adding fertilizer components. Direct activation in the fertilizer solution is also possible but requires higher shear forces.

Create Products That Impress with Outstanding Application Properties!

- More targeted and thus more efficient application enables lower consumption quantities

- No fertilizer losses, direct application to the plant reduces dripping and leaching by rain

- Increased retention time of the fertilizer, ensures better plant availability

Stop run off with VIVAPUR® MCG

YOUR CHALLENGE:

How to Improve Sprayability While Preventing Run-Off?

Problem description:

Xanthan Gum works as a thickener in liquid fertilizers. However, the spraying process becomes more difficult. This places higher demands on the spraying equipment.

How to Solve It

Replace conventional stabilizers, such as Xanthan Gum, to create stable but thixotropic liquid fertilizers.

Which Fiber Works

Microcrystalline Cellulose Gels (MCG) from the VIVAPUR® and ARBOCEL® Fiber Group as a plant-based alternative to classic thickeners, such as Xanthan Gum, which are less thixotropic.

How It Works

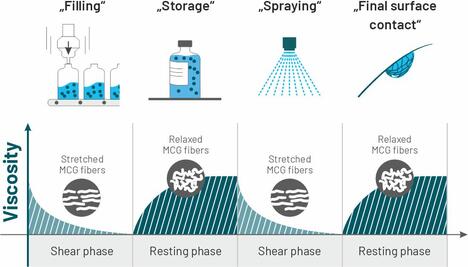

MCG Stabilizers offer flexible viscosity parameters. This mechanical stress during filling and spraying reduces viscosity. At the resting phase in storage and after spreading to the plant however the viscosity increases.

How to Use It

0.5- 2.5% addition in water and activation by shear forces before adding fertilizer components. Direct activation in the fertilizer solution is also possible but requires higher shear forces.

How Thixotropic Thickeners Make Fertilizers Smarter:

Liquid to Solid Carrier

Conversion of various liquids (e.g. oils) into processable powders and granules: The application of liquids on inert JRS Fiber Carriers offers a smart way of integration in dry formulations. This opens up new possibilities in your recipes, even in very low concentrations.

Further Challenges and Solutions in Fertilizer

JRS Plant Fiber Technology has built a total-care system that focuses on all kinds of fertilizers. Using our functional plant fibers you can improve your production processes and optimize fertilizer properties in many ways.

Fertilizer Granules, Prills, mini Prills

Our Team is Happy to Support You

with any requests you have.

Please use the contact form below.

Phone consultation: +49 7967 152-424