Making Food Better with Every Fiber.

JRS Food Ingredients contributes to modern nutrition as a global manufacturer of food ingredients derived from natural plant-based raw materials.

JRS Food Ingredients - We Always Have the Right Solutions or We'll Develop Them for You.

Our product portfolio covers all possibilities: VITACEL® Dietary Fibers and VIVAPUR® Functional Ingredients are suitable for nearly all sort of food applications and a wide range of requirements. Whether dietary fiber enrichment, fat, sugar or calorie reduction, plant-based and vegan products, nutrition for certain phases of life, clean label, gluten-, lactose-free or GMO-free.

With JRS Food Ingredients as your partner, you can fulfill all your consumers' wishes. Perfect cooperation with our customers is a top priority for us and is characterized by security, reliability and trust. We support our customers comprehensively in the areas of, formulation development and test runs for successful product and technology transfers.

Our Expertise

We ensure the use of state-of-the-art technology in our food ingredient production, with a dedicated focus on delivering the highest quality and safety for our customers. To uphold this commitment, we have a global presence with over 90 production facilities and offices worldwide. This extensive network allows us to not only meet all your requirements but also tackle new challenges with sufficient capacity.

With profound technological know-how and a deep understanding of ingredients, we are your qualified partner for new product development. We offer project assistance, formulations, and prototypes for further evaluation, helping save time and money by conducting small test batches before committing to a large-scale production run.

Global Partner

Premium Manufacturer

Technical Support

Sustainability

Discover Our Products

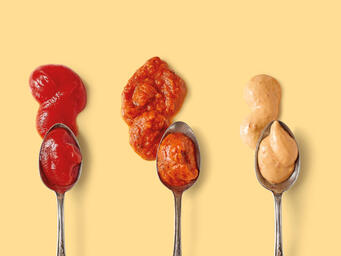

Our portfolio of VITACEL® Dietary Fibers and VIVAPUR® Functional Ingredients fits almost every food application.

VITACEL® Dietary Fibers

As one of the world’s leading manufacturers of dietary fibers, we offer a broad range of types suitable for almost any application, always maintaining the highest quality sourced from natural plant-based raw materials. VITACEL® Dietary Fibers fulfill all nutritional requirements of the food industry.

VIVAPUR® Functional Ingredients

VIVAPUR® Functional Ingredients serve as ideal solutions for addressing texturizing and stabilizing challenges in a wide range of food applications. The VIVAPUR® Functional Ingredients offer tailor-made solutions, providing added functionality, improved efficiency, and cost-effectiveness. Leveraging our extensive expertise and core competence in the latest special milling and blending technology, these Ingredients deliver innovative and customized solutions for diverse food industry needs. Benefit from our years of know-how and advanced processing techniques to enhance your products.

Services & Support

Can we support you with our services? We are happy to assist you during your development process and with the creation of unforgettable and successful product lines.

Get Your Free Sample Now!

Please do not hesitate to contact us to receive a free sample our services and product lines.

Upcoming Events

No entries yet